Production of the cold pressed shea butter of Arc en Sels

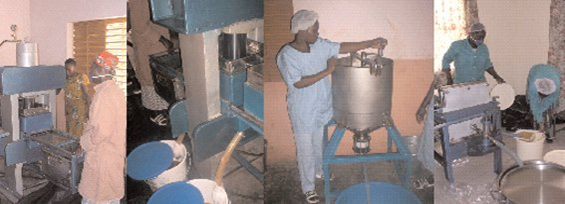

The harvest and the storage of the almonds are done by groups of women from the bush. The truck of the association goes to the villages to get the harvest and bring it to the center where it is stored. the cleaning and the drying of the almonds are done there, followed by the cruwhing with an electrical grinder.

The roasting is done with natural gaz fire.

It allows to get rid of all the enzymes leading to bad smells. Unlike the wood fire, the use of gaz avoid the smell of smoke in the butter. After going into the mill, the produced paste is put into nylon fabric pockets which act as filters once put in the press, and let the oil pass while keeping the solid residue.

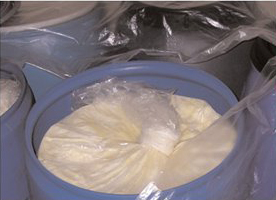

The butter thus obtained, still liquid, is mixed with purified water and placed in slow agitation bath to get rid of the last residue. By decantation, the particles are removed with the water.

The butter is warmed till 60°C to remove all humidity. The oil is then filtered (3 times) in a press, and stored in drums in a air conditioned area, before it is shipped.

The more the residues are removed from the butter, the less smell it will have, and the longer it will last.

This process offers all the hygien garanties for the production of a high quality product which keeps all its vertues. The efficiency is 30%, 3 kg of fruits give 1 kg of shea butter .

The organic shea butter of Arc en Sels is of superior quality and gathers all the conditions of respect, for the environment as well as for the human beings.

Extracted by press, it garanties a superior quality and the hygiene of the production. With this principle, it keeps all its properties (vitamin A, D, E, G and its latex).

ARC EN SELS’s difference is clearly:

The traditional shea butter is extracted by churning, which means it stays in contact with water, which lead to the corosion of the butter, and reduces its conservation. The hygiene conditions are not the best neither.

Some of the European laboratories buy this butter at very low rates, approximatively 0.7 cts with barely allows the women to live. It is the same with some so called fair trade organisations which look for the lowest price instead of quality.

This butter is then refined and chemicly treated to have a uniform appearance. It can even be mixed with palm oil to reduce the cost. The shea butter then brings no prosperity at all to the african women who are producing it, and none of the vertues for the health and beauty of the body.